Industries We Serve

Packaged Ice

Vogt Ice revolutionized the packaged ice business in 1938 by development of the first automatic sized icemaker, the Tube-Ice machine. Before that, ice was delivered in block form for the use in ice boxes or chipped into smaller pieces to ice down drinks.

The packaged ice industry has come a long way since its humble beginnings to become a thriving, profitable business and Vogt Ice has been there every step of the way assuring success for the iceman. Every successful iceman knows that the key to success is to have a dependable source of ice. Vogt offers a full line of Tube Ice machines ranging from 3 tons a day to over 100 tons per day to suit your needs. Our reputation for dependable, long lasting, efficient equipment is second to none. Vogt Ice has thousands of machines in packaged ice installations around the world many of which have been in service in excess of 30 years.

Benefits of Owning A Vogt Ice Machine:

- Lowest cost per pound of ice over the long haul by efficiencies gained through utilization.

- Most reliable, durable, high quality product in the marketplace.

- Energy and water efficient.

- Competitive extended warranties (25 year evaporator warranty).

Commercial Food Service

Customers come first for you and for Vogt Ice. Whether you are providing ice on flights, in hotels, restaurants, amusement parks, casinos, schools or in prisons, your specific ice needs are important to us. Our experts help take the worry out of the ice making equation. Vogt’s high capacity ice machines have a proven track record. All machines are built to endure. Remaining operational is critical to your success. At Vogt Ice, the end result for you and your customers in providing ice as often and whenever needed without interruption.

Fishing / Seafood Icing

Fresh caught, processed fish and shellfish products requiring preservation of quality with ice.

Ice is used at all points in the chain of handling fish and seafood – on board vessels during the catch, dock side to preserve the fish during transport to the market or processing area, central processing areas, and transporting of fish and seafood after processing requires continuous temperature control to maintain the best quality and extend the shelf life. The use of ice reduces bacteria or enzyme activity in seafood products, slows decay, and yields a higher quality grade. Ice provides a sanitary means for this preservation.

Poultry / Meat Processing

In order to maintain the quality of poultry and meat products during processing cooling is needed in various parts of the processing. Some of these requirements can be satisfied with chilled water or glycol; others require ice. Reducing the temperature as quickly as possible through initial processing retards microbial growth and slows deterioration. Both increase the shelf life and freshness of the product. This goal can be met with chilled ice water.

Vogt offers a number of icemakers suitable for poultry and meat applications using both HFO blends and ammonia refrigeration. Ice can be produced continuously to meet the ice requirements as it is needed or during non-production period and stored for later use.

If the ice requirements are met using icemakers to produce the ice as it is required, a larger icemaker is typically required. This method eliminates the need to store ice – ice is delivered directly to the mixing process. Smaller icemakers can be used with the addition of ice storage and production of ice during non-production hours.

Ice is needed for fresh product being sent to market or to further processing facilities. Fresh poultry that is packaged for shipment and not frozen requires a cooling medium that is long lasting and low in temperature to ensure the quality and freshness are maintained during transport to the end-user. Ice is typically used to top ice the product even in refrigerated truck and rail cars. The ice maintains contact with the product and maintains the desired temperature. At delivery the presence of the ice ensures the end user that the product temperature was maintained through the entire shipping process and is still fresh.

Produce Cooling and Icing

Fresh vegetables and fruits products require ice and/or chilled water for preservation of quality. Ice and/or chilled water are used at all points in the chain of produce processing – ice is added during harvest process to start removal of the field heat from the product, top icing during processing, and liquid ice injection of boxes prior to shipment to the market, or central processing areas, or the end user.

The objective is to maintain the temperature during all phases – from the harvest to the final destination in the restaurant or consumer’s home.

To fully retard or inhibit bacterial growth after harvest, ice and chilled water are used to remove heat, clean, and extend the shelf life of the product- deliver a crisp fresh end product to the end-user. Using potable water in the production of the ice and sanitary handling of the ice after production is the only way to assure ice cleanliness.

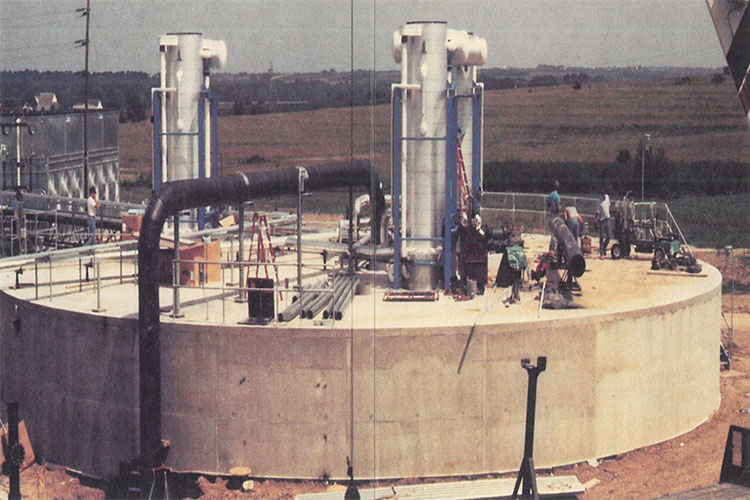

Concrete Cooling

Use: When concrete cures at temperatures above 70°F the results are loss of strength, more cracking, rapid setting (need to finish quickly), and increased water demand. These detrimental effects can be offset by cooling the aggregate (using ice in place of water in the mix of cement and aggregate).

Typical applications:

- Dams for inland reservoirs.

- River lock and dam systems.

- Highway construction.

- Large general construction pours.

- Critical strength specifications for concrete must be met.

- High ambient temperatures are experienced.

- Areas where aggregate temperatures are high.

Baking Industry Applications

Bakery products, primarily breads, sweet rolls and buns are high production volume and temperature control during the dough mixing process is critical to the final quality. Principle sources of high temperatures are the heat of hydration (flour absorbing water) and heat of friction (mixer motor energy).

To offset the principle heat factors in the mixing process consisting of the heat of hydration (flour absorbing water) and heat of friction (mixed motor) chilled ice can be added to the mixing process. Vogt Ice has a range of capacities for either Tube-ice or crushed ice to meet each individual customer’s needs.

Chemical and Dye Processing

Chemical and dye processors are increasingly finding a need for large quantities of ice in their chemical mixing and reaction procedures. Ice has been used by many major chemical processing plants to control the temperature of chemicals during reaction, to add water to a process while cooling or for fast cooling to stop a timed reaction.

For faster cooling, ice is preferred to traditional jacketed tanks or external heat exchangers. Adding ice to a solution subjects it to a much larger cooling surface area, lowering temperatures in less time and maintaining better control. Ice can be fed continuously, or at specific times during the batch processing. Ice is now being used in a variety of applications including organic dyes, dye processing and the manufacturing thermal sensitive paper coatings.

During the mixing process heat is generated in the reactors and a means to maintain a stable temperature is essential to the process. Ice can provide the required cooling using a variety of Vogt icemakers.

Vogt Ice machines offer an advantage over other ice making machinery due to the unique freezing process. The Vogt Tube-Ice machine circulates water through tubes and frozen from the outside in. As the water freezes. impurities are washed away. Ice from Vogt Tube-Ice machines is purer and contains as little as 1/3 the dissolved solids as the water.

Thermal Energy Storage

The Tube Ice design operates without a cutter to maximize capacity and is located directly above the storage tank. Water is circulated to a tank above the stainless steel tubes and flows down each tube forming ice the length of the tube. At the optimal thickness, warm refrigerant enters the vessel and the ice releases from the tubes and drops into the storage tank. The harvest process causes the ice to break into much smaller pieces allowing for better heat transfer characteristics when the load occurs.

The cycles are repeated as long as there is need for additional cooling reserves. This continuous ice making capability is impossible with systems where heat transfer coils are submerged in ice storage tanks because the ice making surfaces become encased in ice, insulating the heat transfer surface and reducing the efficiency of the system, while waiting for a thaw before production can resume.

Features:

- Infinite available surface are of ice for quick release of cooling to the load.

- The ice machine acts as an efficient chiller when not making ice.

- Low temperature water (33° F) can be generated for economical water distribution (pumps, piping) to the cooling load.

Typical applications:

- Chemical processing requiring jacket cooling.

- Dehydration processes.

- Dairy-Pasteurization and blow molding processes.

- Clean room air conditioning.

- District Cooling (airports, hotels, business centers).

- Intel air cooling for combustion turbines.